Metal Finishing System

Metal Finishing System

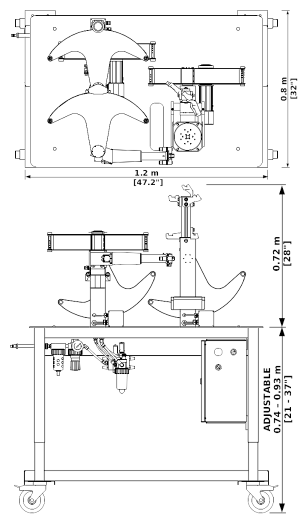

The Touch Robot Metal Finishing System is a compact robotic system made up of a 4-axis, low-inertia, contact-compliant arm working in concert with a 2-axis part positioner. The arrangement combines the dexterity and sensitivity of the robot with the power to manipulate heavy castings.

The unit comes pre-calibrated and mounted to a 4′ x 2-1/2′ portable work table. It uses industry-standard hand material removal tools such as belt and die grinders. Parts up to 16″ long, 8″ wide, and 25lbs in weight can be accommodated. Larger parts are possible with modifications.

It requires only 400W @120VAC and 90 PSI shop air to operate. Its safe, rugged, and portable design allows it to work virtually anywhere needed in the plant.